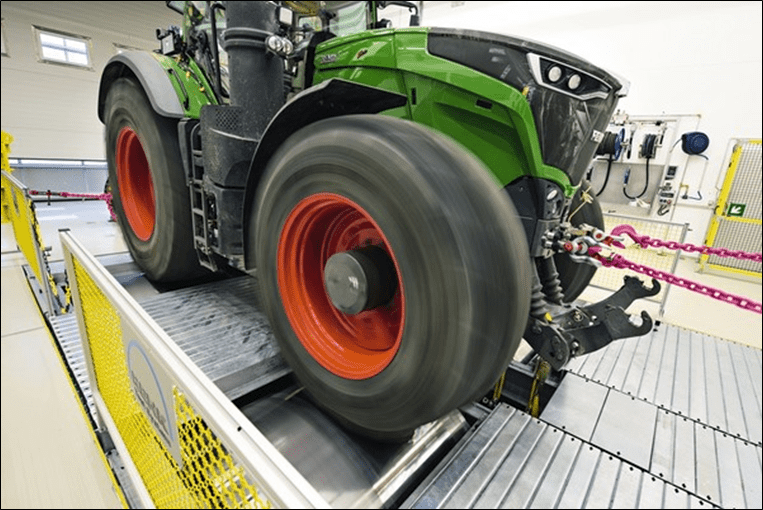

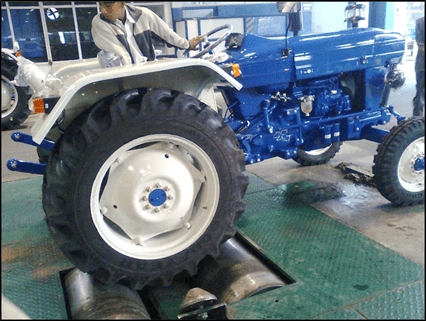

Tractor Chassis Dynamometer Test Bench

Operation Philosophy

It is a customized special End Production Line Roller Test Bench for 2/3/4 wheeler vehicles (including multi-axle vehicles with 4×2 / 4×4 drive) Comparative test performance in Production & Quality Centers, Vehicle Repairing / Repairing / Re-building Centers, Educational Institutes, etc.

This system is especially designed to check following parameters of vehicle.

- Speedometer / odometer.

- Acceleration / deceleration.

- Waukesha Gas Engine is communicated by Modbus.

- Fuel consumption.

- 4W/2W function testing separately by high speed hall effect sensors.

- Hydraulic load test.

- Vehicle drive ability and Visual checks.

- Functioning of lights, vibration and leakages.

- Check vehicle gear transmission.

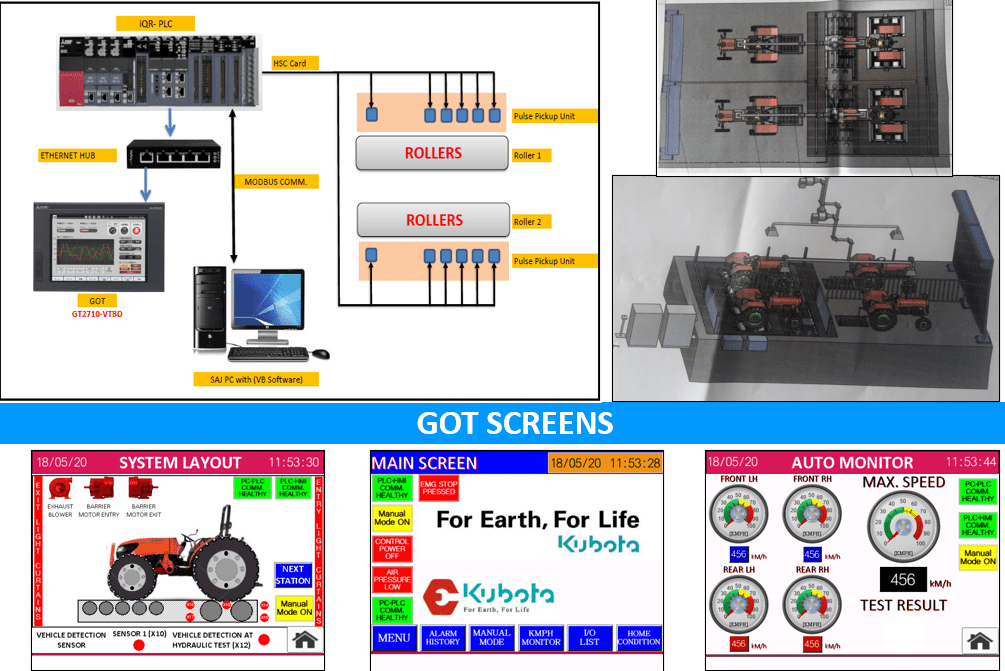

System Layout & HMI

Features

- System with 128 DI/DO , 8 AI/AO & 12 High Speed Input

- Vehicle Speed Accuracy is very important & we achieved within difference of 2-3 rpm

- Speed difference in PLC reading and Tachometer reading is less than 1 Kmph.

- MODBUS Ethernet communication with SCADA software for fast data transfers.

- Easy to diagnose machine alarms in GOT with troubleshoot manual PDF display on HMI screen.

- Critical point is to identify RPM from 12 different sensor in Front wheel roller

- RPM and result repeatability was also crucial part of Testing

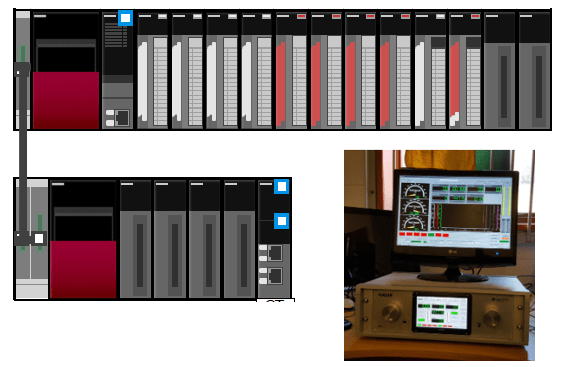

Configuration

- PLC – R04 CPU iQR Series PLC

- GOT- GT2710-VTBD Series.

- High-Speed Counter module - RD62P2E

- Ethernet Module- RJ71EN71