Assembly and Testing Line

- Home

- Assembly and Testing Line

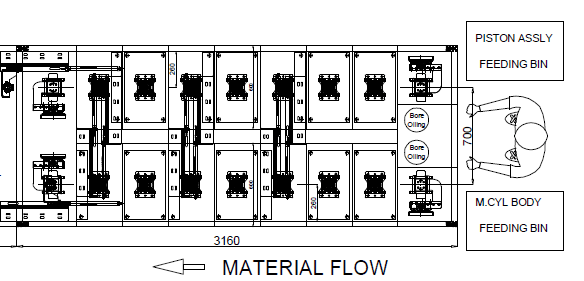

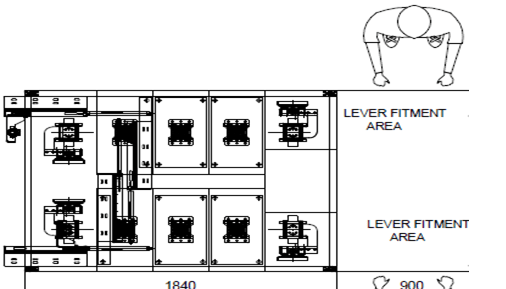

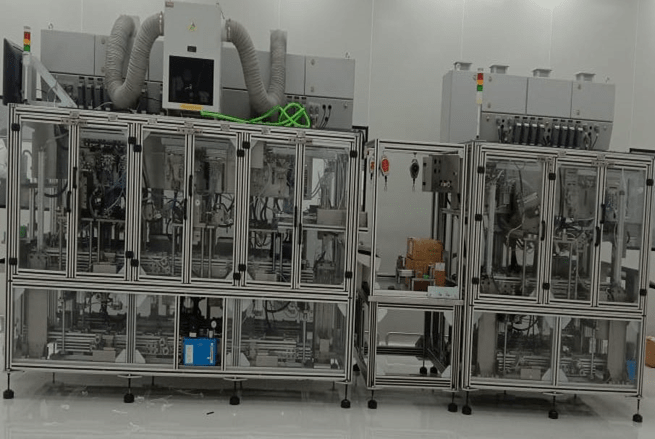

Master Cylinder Assembly Station

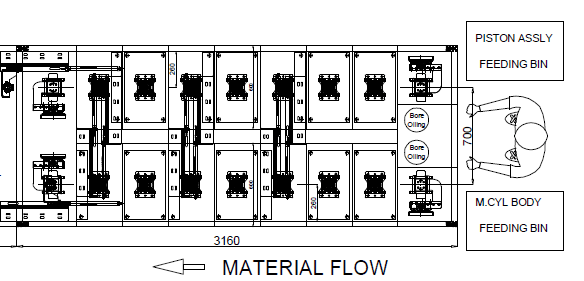

Part A

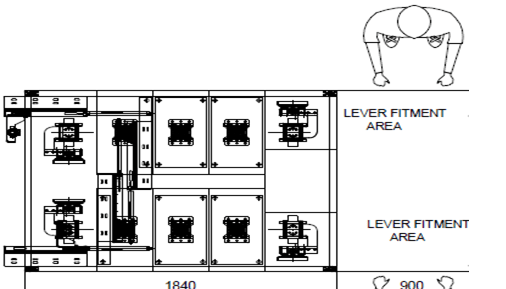

Part B

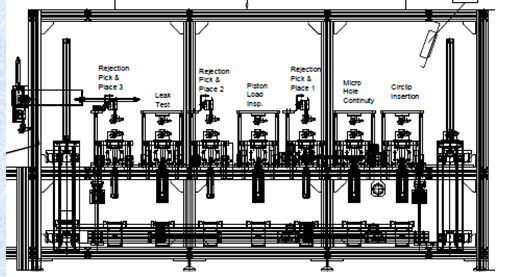

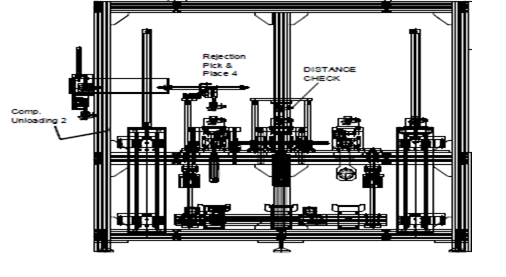

Operation Philosophy

- More then 500 IO’s used in the system.

- Only one operator can handle both LH and RH system.

- So that there is man power reduction.

- Also all stations req. very less space.

- Part A cycle time is 31 sec for LH & RH.

- Part B cycle time is 26 sec for LH & RH.

- Due to combining all system in one assembly line so less maintenance is required.

- At TV we can monitor actual production and OK & Not Good status of individual system.

Features

- Cycle time is reduced by implementing combined system instead of individual machines and also maintaining is also made easy.

- Servo is used for walking beam means position can be changed anytime reducing maintenance and regular sensor adjustments.

- TV in linked with GOT to monitor data.

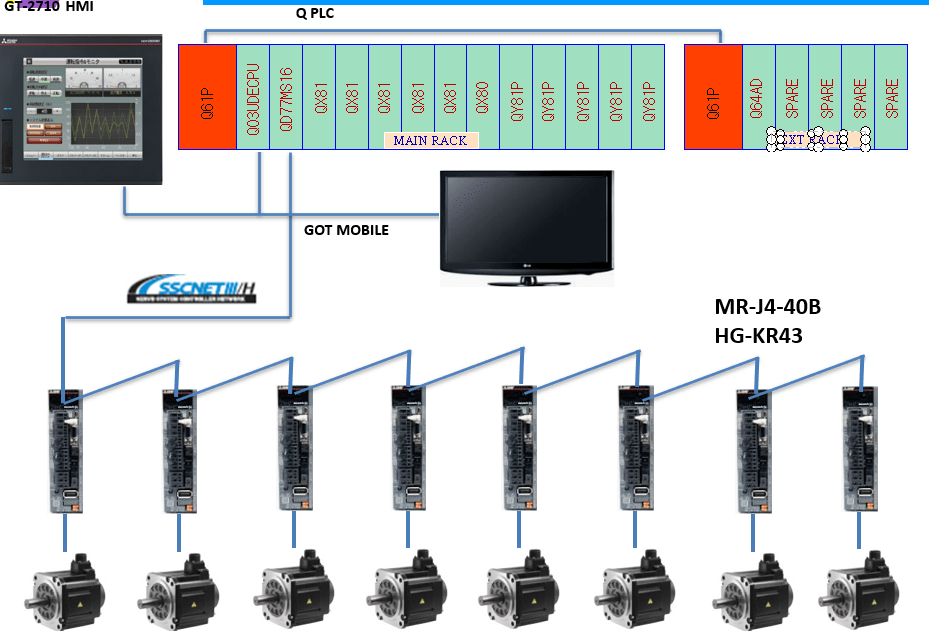

Configuration

- PLC – Q Series & FX5U

- GOT-GT27 Series & GS Series

- Servo - J4 Series with SSCNET technologies