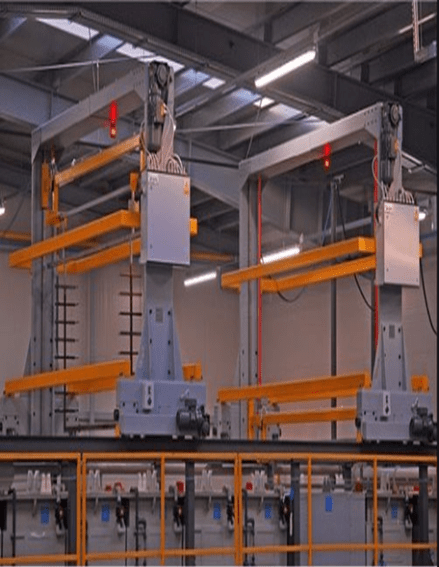

Transporter System

Operation Philosophy

- This is Chemical Electroplating Process.

- Where Process Timing is Critical Point.

- PLC Controls the Process Sequence with Settable Timing by Customer.

- Process/Tank Sequence is also Settable.

- Both Transporter will Work with there given Sequence.

- In Power OFF Condition Sequence is Retained So no Process Loss

- The press cycle called as TMC Cycle

- Anti-collision sensor available at both Transporter for safety purpose

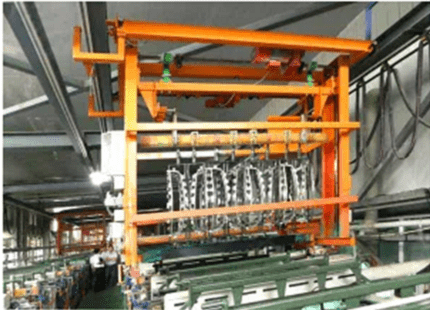

System Layout & HMI

Features

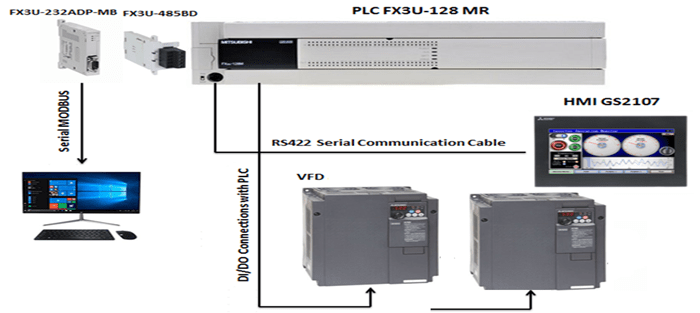

- System with 128 DI/DO, VFD & SCADA

- Critical Part is to achieve the TMC Cycle

- Both Transporter is used with Multiple Speed Combinations using VFD Multiple Speed function

- SCADA Shown real time Animation of Movement

- Timings of Process can be changed in running

- PLC core Logic theme was GET & PUT

- Anti-collision Sensor used for both Transporter

Configuration

- PLC – FX3U-128MR.

- GOT- GS2107 Series.

- VFD- FR-D Series.

- SCADA- Ellipse