Operation Philosophy

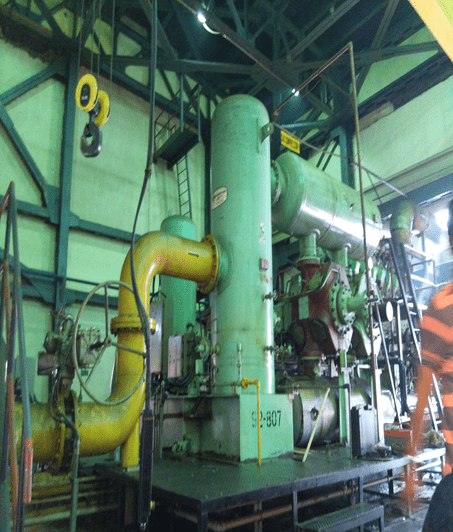

- We have to boost Natural gas pressure from 3.5 Kg/cm to 21 Kg/mm to run the turbine.

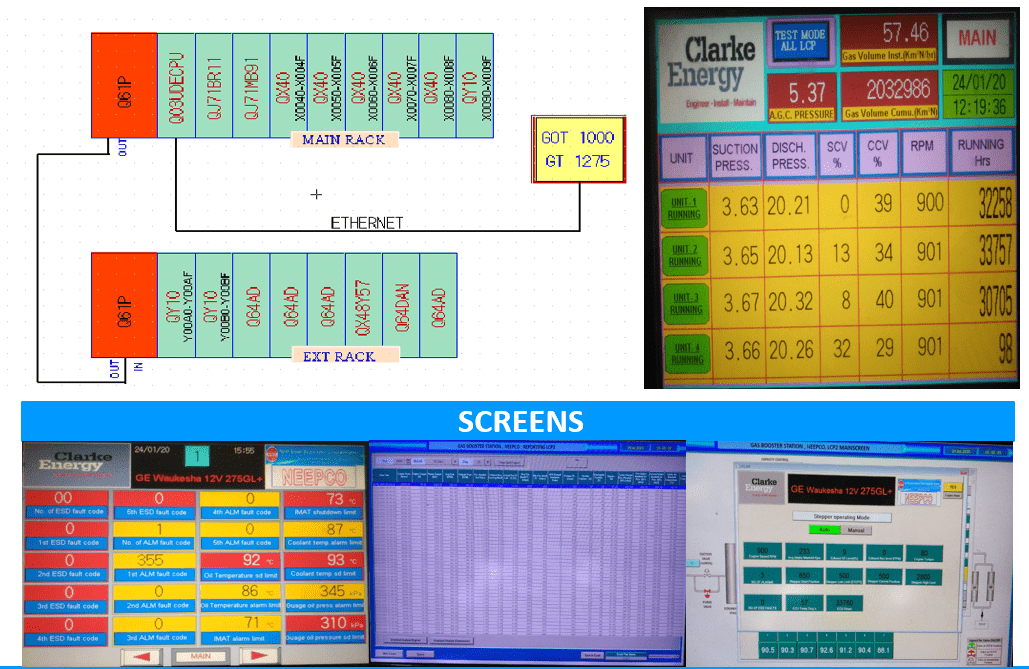

- Local control Panel controls Waukesha Gas Engine and compressor.

- Waukesha Gas Engine is communicated by Modbus.

- Purge system is used to avoid spark at panel.

- To maintain pressure at the system PID controllers are used.

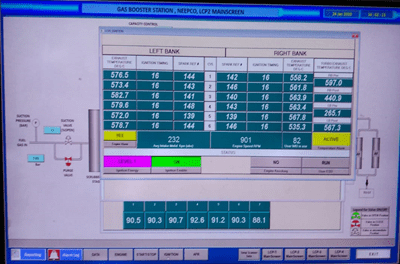

- All engine parameters and Gas flow meter parameters (Approx. 100 parameters ) shown at HMI and scada screen.

- Data logging for some important 90 parameters to track 1 sec data.

- We have to boost Natural gas pressure from 3.5 Kg/cm to 21 Kg/mm to run the turbine.

- If Gas pressure is down due to other panel trip, then PLC can take care Discharge pressure by increasing Engine speed from 900 rpm to 950 rpm.

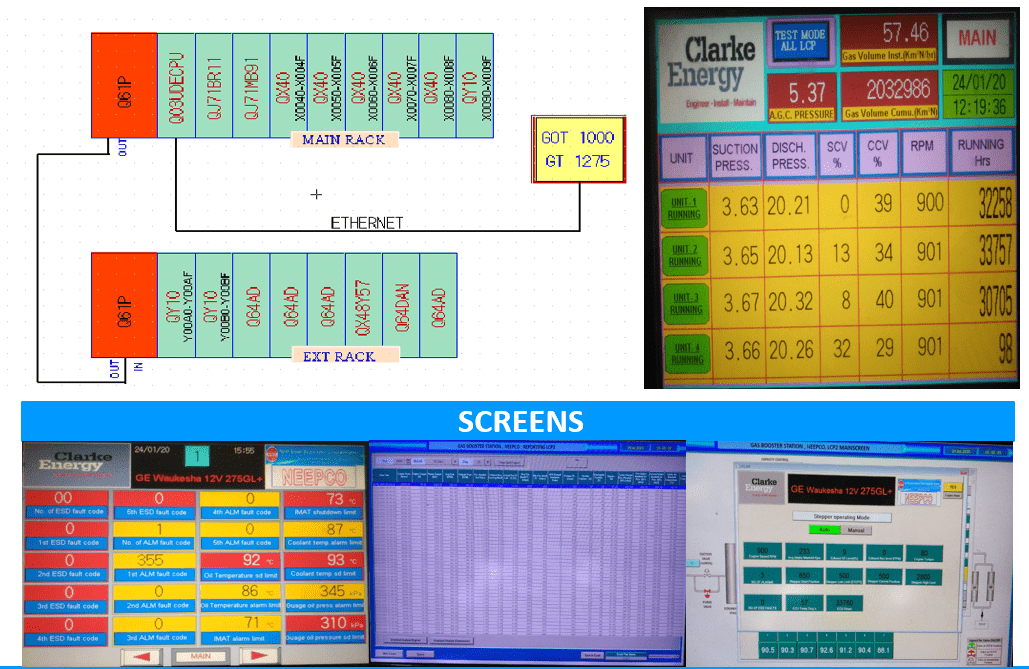

System Layout & HMI

Features

- We can monitor all data at 800 meters.

- PID controller is provided to maintain pressure for 3.65 Kg/cm2.

- Capacity control PID is provided to take load..

- Manual and Auto control mode are provided at PID.

- Melsec N/W is used to transfer all data to Master.

- DPM’s are used to monitor different Temperature and pressure of the system.

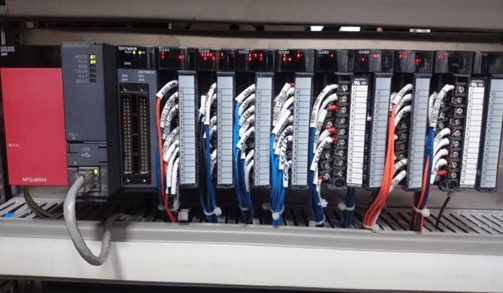

- 80 Input and 48 Output.

- 16 AI and 2AO.

- 7 Digital panel meter.

- 2 PID controller.

Configuration

- PLC – Q Series .

- GOT-GT12 Series.

- Melsec N/W – QJ71BR11.

- Modbus N/W – QJ71MB91.