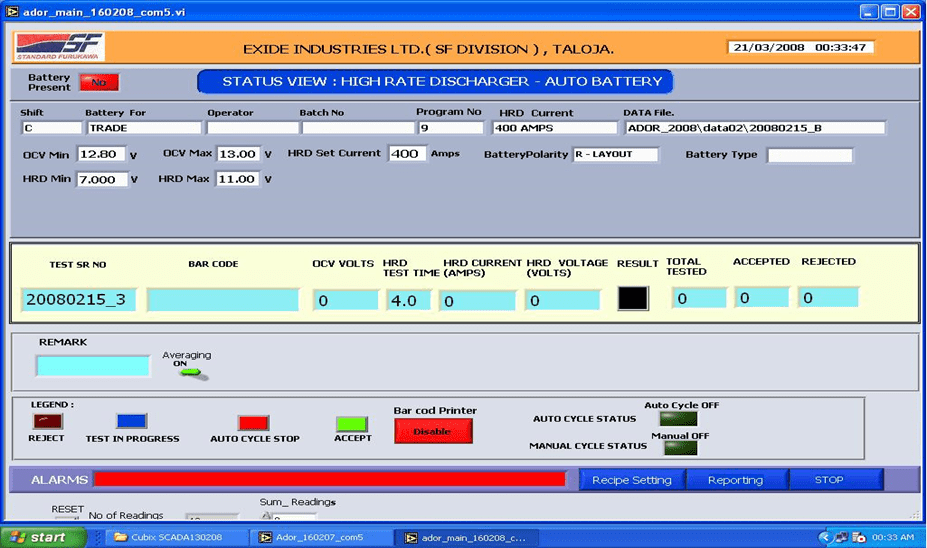

HRD – High Rate Discharge Battery

Operation Philosophy

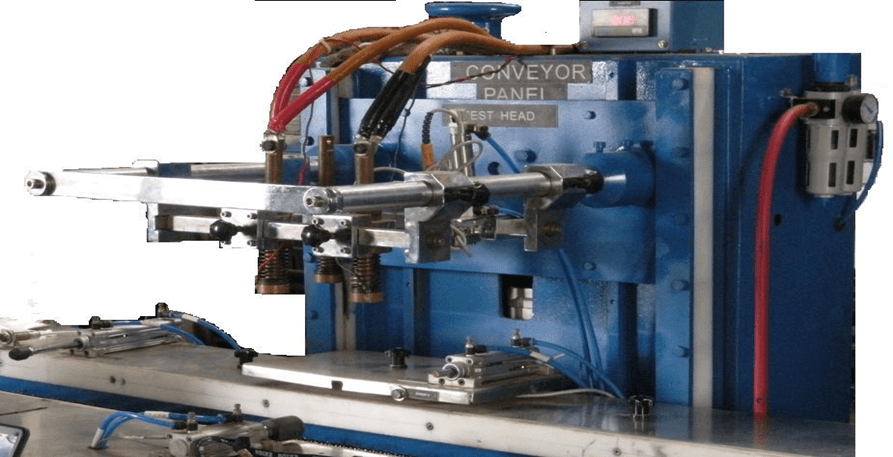

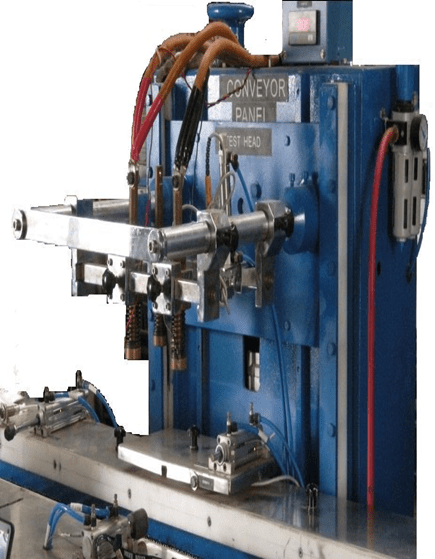

- The HRD is designed for high rate discharge testing of automotive and batteries. The operator can perform a short test on each battery to find defects such as poor welds, reversed plates, and poorly formed batteries.

- The working head is equipped with pneumatic clamps for clamping the battery terminals, which provide a hermetic contact with the terminals.

- Installation of clamping tools for different types of batteries is easy and fast. The machine is equipped with a motorized conveyor with a simple and quick adjustment of the guides.

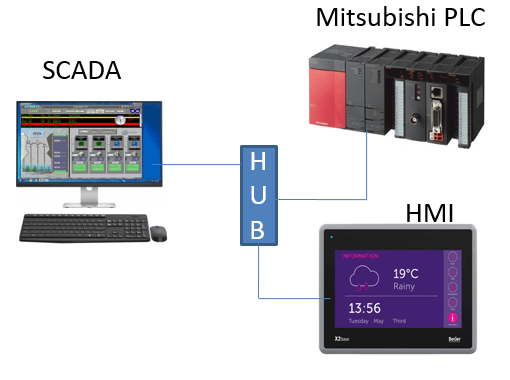

System Layout & HMI

Features

- Test Time : - 2 Sec (min.)

- Current Ramp - up time : 4 mSec

- Current hold time: 2 Sec

- Current Set Range: 0 to 1000 Am

- Current Rising ,Holding.

- Total closed loop control system.

- In this case nonlinear FB 0 to 75 (mV) from the Current System.

- Bar code Scanner and printer interface with PC for the data recording of each Battery on moving conveyor line.

- Online Data Logging to PC.

- RECIPE setting Facility from PC and

- HMI to facilitate the auto cycle RUN without PC.

Configuration

- PLC – Mitsubishi PLC

- HMI - Beijers HMI

- SCADA – LABVIEW