Application Details

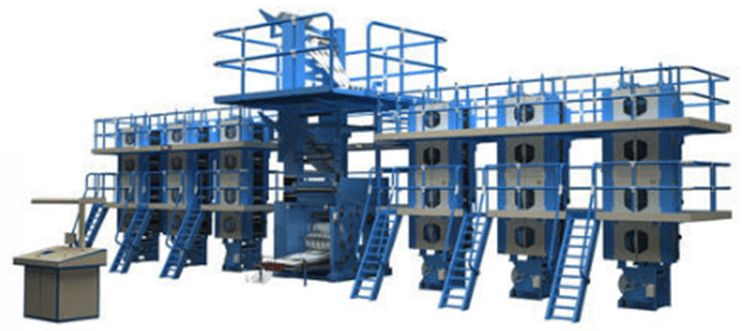

- This is a multiple roller ink transfer system for high speed newspaper printing machine.

- Here, the amount of ink transfer is controlled by precise and high speed Mitsubishi PLC system (replaces an Imported Controller), thereby ensuring cost effective automation system with local service backup.

- Ink delivery is controlled with precise high Frequency switching. This way, darkness of printing is controlled.

- Flexible controls for each color are used to achieve best color balance and perfect tone of printing.

Challenges & Complexities

- High speed Spray Bar operations with precise control over on time, up to 1 millisecond.

- As machine size is up to 50 meters, remote IOs are used for reduced length of cabling and installation time.

- Program is developed, in a structured modular form. Hence, gives flexibility w.r.t. Number of tower, which can be enabled/disabled through HMI.

- Various types of controls are added to this automation system to offer best performance and speed.

- Various Options and Modes are added for operator convenience.

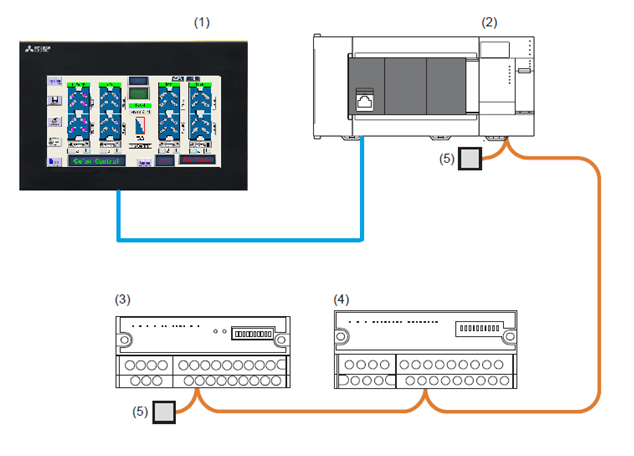

System Layout & Network

- Touch HMI (GOT), 7” Screen

- Modular PLC with Remote IO Master

- Remote Input Module

- Remote Output Module

- Termination Resistors

Operation Philosophy

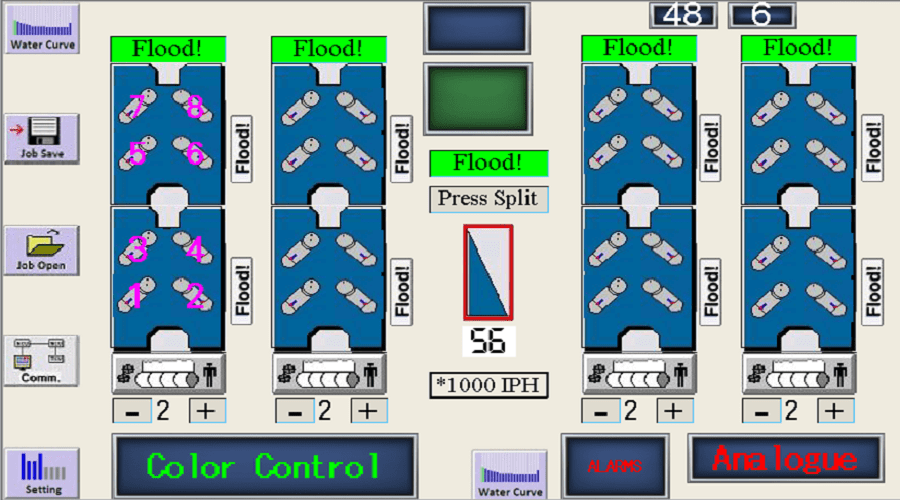

Flood is amount of Water delivery to Printing roller.

Amount of water changes amount of Ink delivery to Paper.

Touch HMI (GOT) Screen

For controlling ink delivery, Color and Water delivery is adjusted as follows

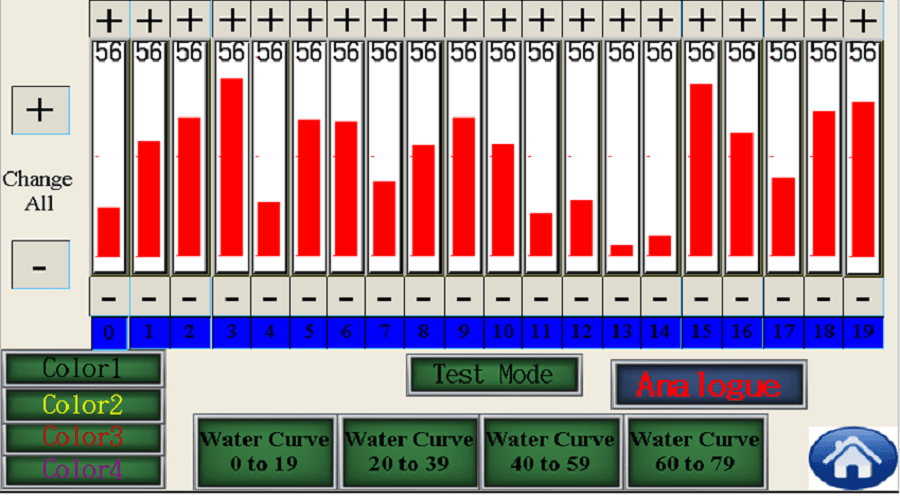

Features of the Control System

- There are 4 Towers and 4 Nozzles for 4 Color printing.

- Color control by Flood setting is done by controlling high speed operations of the Solenoids.

- Spray Bars are managed in Test (Manual) Mode and Analogue (Auto) Mode.

- Individual Flood is set, as per sensed speed or overall flood also can be increased or decreased.