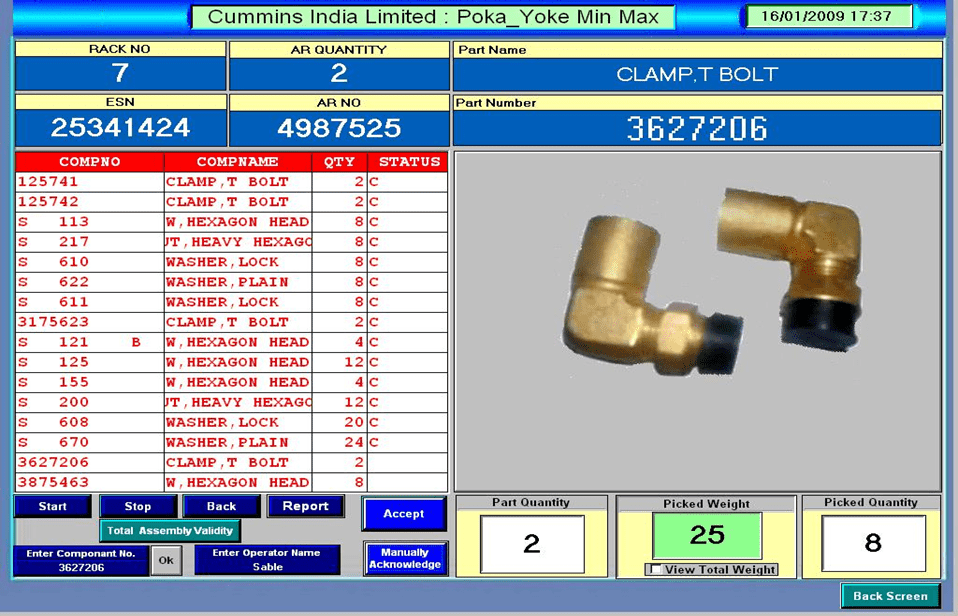

The Poka-yoke system implemented in Cummins India Ltd is developed for collecting the engine parts from racks/bins for final Engine assembly. The SCADA PC is a Oracle Client. It is connected to the Main Database Oracle Server. The Production Planning sends the Engine data to EDP dept which updates the database and is fetched by the SCADA PC.

Operation Philosophy

Oracle Procedure

The Operator selects the Engines from the Engine List. On pressing of Start button, the different components in the Engine are listed on the Screen. Its corresponding LED on that rack/bin start glowing. Out of them 1 LED is flashing which is indication to operator to take out that part first from that bin. After taking it out, he presses Acknowledge PB on the rack. Then the next LED will start blinking and first will be OFF.

The respective picture and related information of the component to be taken out is displayed in large view on the PC screen.

The PLC works as a multiplexer. It scans all Outputs row and column wise continuously. When a list of bin’s is received from SCADA , PLC calculates corresponding O/P’s and sends that result to PLC physical O/P and the corresponding LED on the rack/bin glows

SCADA Screen

Features

- Oracle Connection through ODBC.

- Production supply chain system time is drastically improved.

- 0 % Mistake chance of picking wrong component while collecting material for engine assembly.

- Layman can operate this system easily.

- Latest Production data fetched by SCADA

- Multiplexing in PLC to reduce PLC Outputs

- Visual display of every Engine part on SCADA screen.

- Ease to handle and diagnose.

- Printout of Material List at the End

- In case of customer complaint historical data tracing is possible.

Configuration

- PLC – FX series

- Scada : Elipse 2.29

- Database : Oracle