SAND CONVEYING SYSTEM

- Home

- SAND CONVEYING SYSTEM

Operation Philosophy

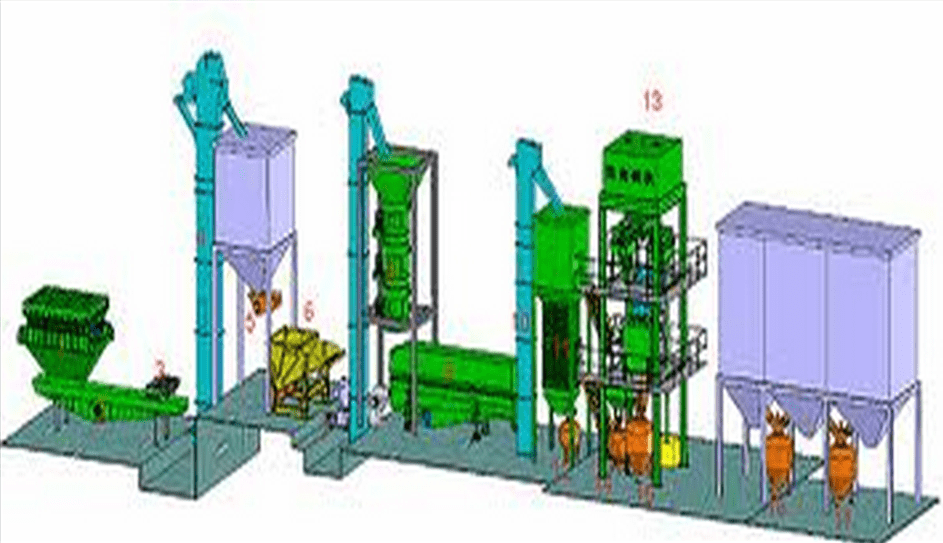

- System is used for providing sand in Foundry Plant.

- Sand is convey to all Susha M/C as per their Call Sequence.

- M/C use this Sand for Moulds Production of diff.Parts of Automobile.

- Three type of Sand – E,ES & F are used for different mold.

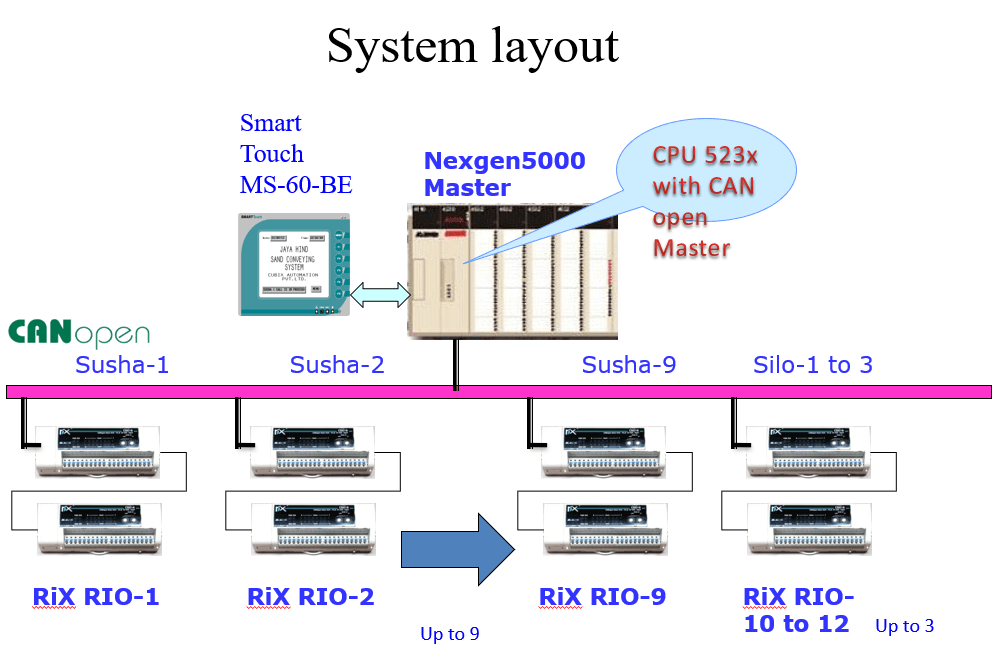

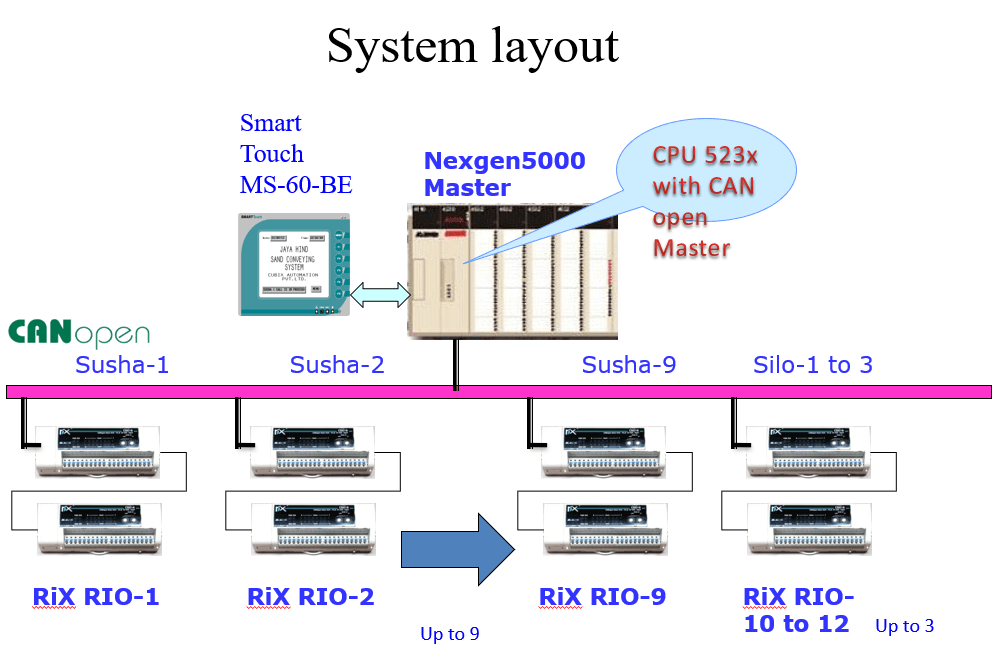

- We used Can-Open Network for connecting all M/C to N5K PLC.

- Silo of three type Sand is connected to same network.

- HMI is gives Call & Conveying Status of System.

Features

- Sand conveying system controlled through CAN network communication.

- Main PLC and distributed IO hardware is compatible for dusty environment

- Special PLC algorithm written for call sequence as per sand requirement to machines .

- Different Three type of Sand – E,ES & F can able to select through the HMI as per machine requirements.

- Indication display given where operator can see the status of his call for SAND.Like waiting , running ,completed.

- Silo of three type Sand is connected to same Can-Open Network of M/C PLC

- HMI is gives Call & Conveying Status of System.

- All Faults and error monitored on HMI

Configuration

- PLC – Nexgen 5000 PLC

- HMI - Smart Touch MMI

- Servo - Remote I/O module

System Layout and HMI