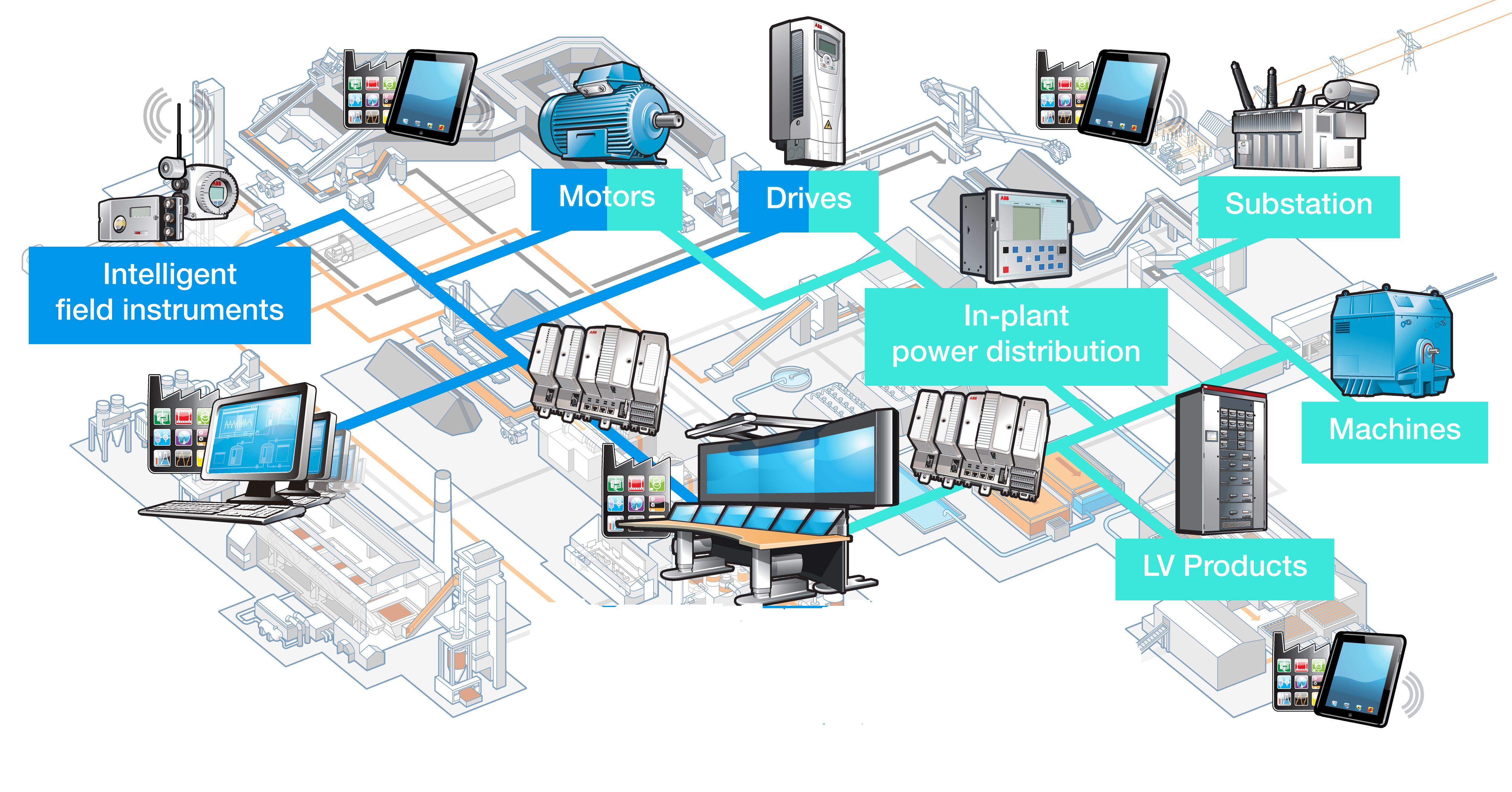

Automation Products fail to deliver desired results or fail in industrial or process applications, if the automation users do not select right products & take care of Value Engineering, Safety for these applications.

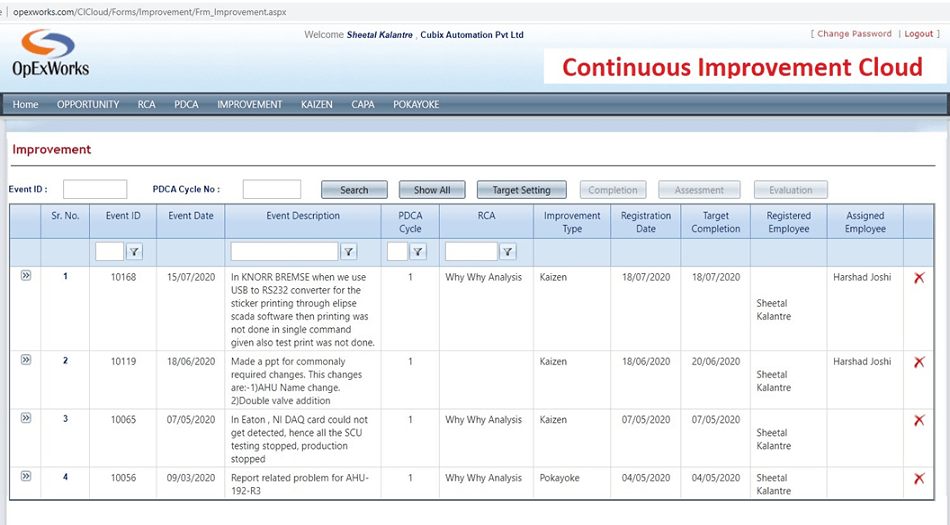

Here, Cubix Automation possesses deep knowledge & field experience of selecting the right products, also bridging the gap between the latest state of the art World class Automation Technologies and its Integration to create Value Engineered Solutions, with enhanced Performance & create Win–Win situation for Customers & Principal Partners.

Thus, Cubix Automation enables Original Equipment Manufacturers (OEMs), Machine Builders, End-users to design & implement Factory Automation Solutions to deliver optimized Price Vs. Performance for their machines, equipment, facilities & processes. This also protects their automation investments in the long run.

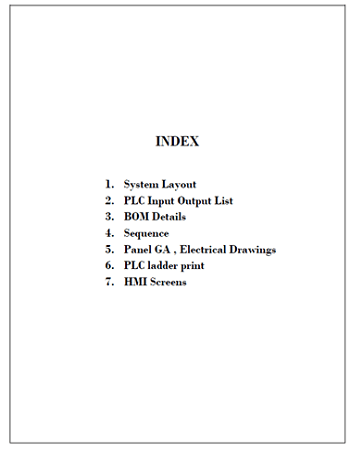

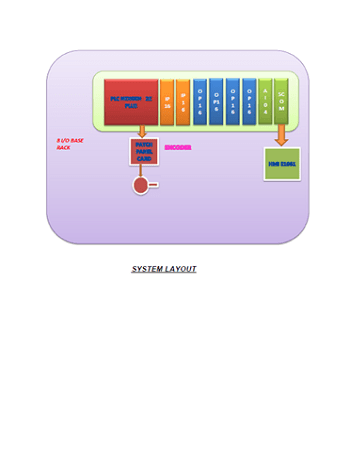

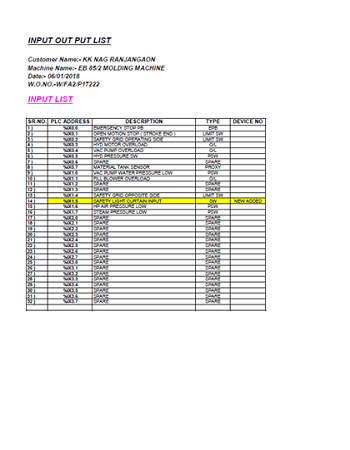

- Preparation of Control philosophy & Configuration drawings

- Project Hardware & Software selection

- Panel design and Cable Scheduling

- Third party devices Integration & Testing

- System Functional Testing as per the Customer requirement

- Final Inspection by the Customer / Factory Acceptance Test (FAT)

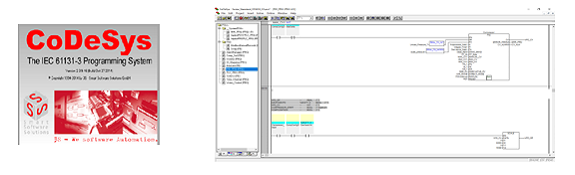

- Plan & Preparation of Flowcharts, Algorithms for Control Philosophy

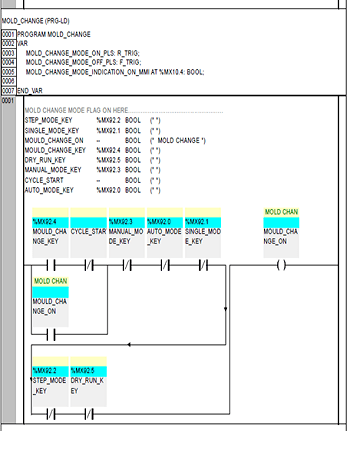

- PLC Programming Software, Suitable for all Mitsubishi PLC such as GX Developer / CoDeSys

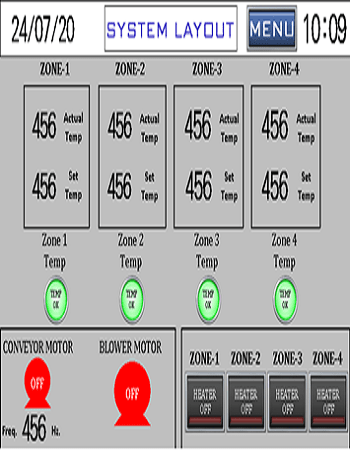

- GOT / HMI Programming Software

- SCADA Configuration

- Ladder Logic & HMI Screen / Software development

- Driver development for Third party Devices

- General Arrangement Drawings, Loop Diagrams, Field / Panel Interconnection Diagrams, using Auto CAD / EPLAN

- Technical Support, Installation & Commissioning Services, as per Scope of Work

- Documentation in form of System Operation & Maintenance Manual

- System Operational Training to the Operators, as per SOP

- System Maintenance Training to the EU Maintenance team

- Soft Copy of Detailed Documentation Set, post Successful Trials / Site- Commissioning & Completion of the Project

- These documents enable identify the faults easily & in turn, reduce Machine Downtime

- Project / System Handover Meeting with Share Photographs

- Pre-sales Support in form of System Configuration, BOM Selection with Application Engineering for Optimum Cost-effective Solution

- Product Obsolescence Analysis & Migration Plan with Spares recommendation

- Rising costs due to rapidly evolving technologies & training solutions

- Maintenance demands from Complex Control Schemes done in the past and Constantly Changing Software’s & versions

- Critical Asset / Equipment Management, Program / Data back-up management & Reliability Consultancy

- Reducing and managing energy consumption

- Difficulty lowering lifecycle costs and generating expected returns

- Complying with changing regulatory and safety concerns

- Safety assessment & Solutions