Juice Processing Machine

- Home

- Juice Processing Machine

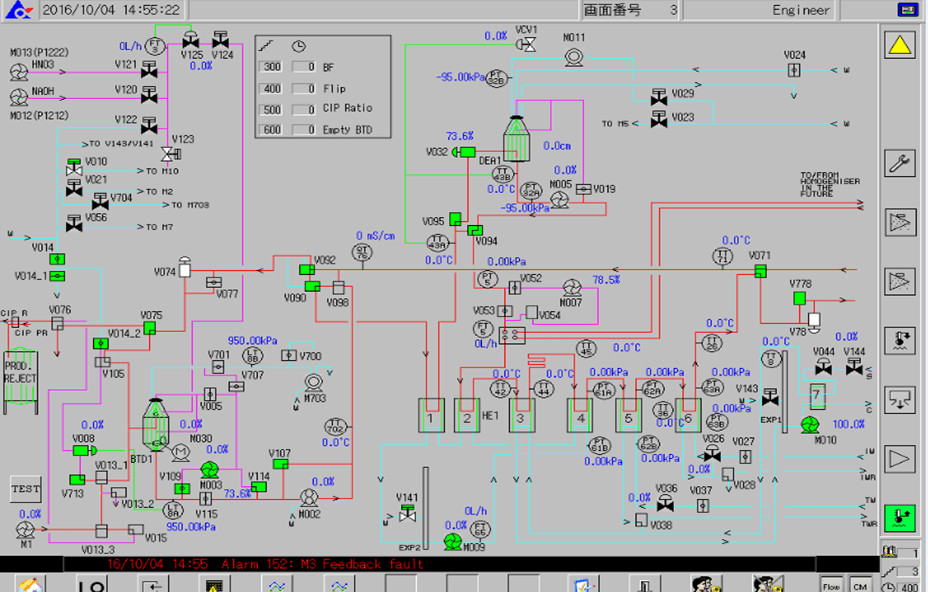

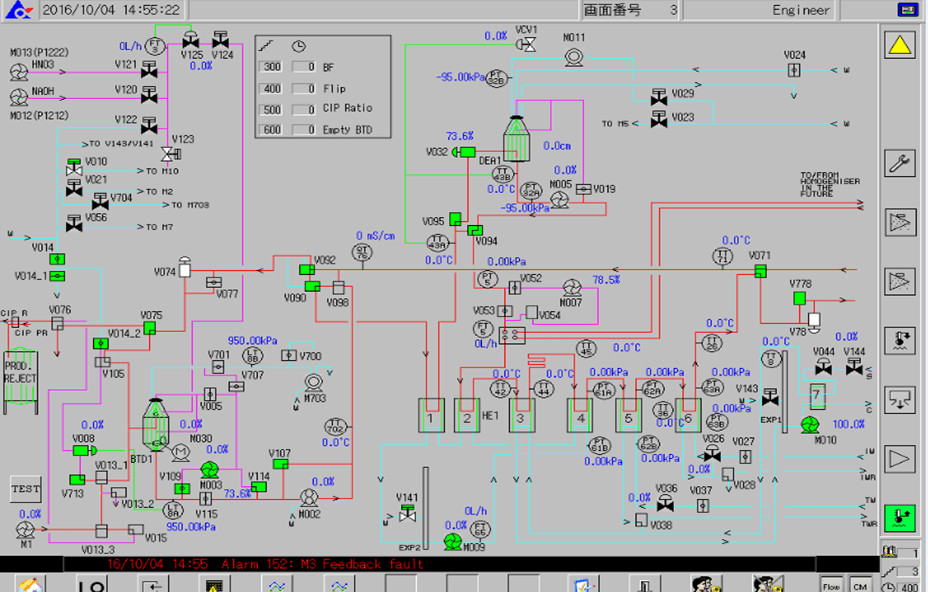

Operation Philosophy

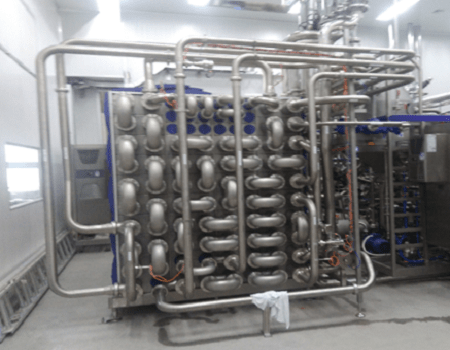

- Therm Aseptic Drink Machine for Juice & Tea Product

- Process Plant with Ultra High Temperature Technology ( UHT )

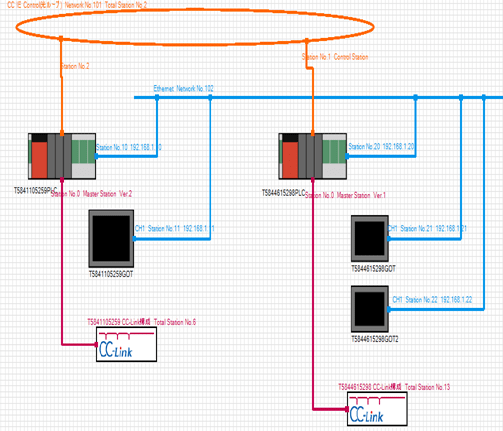

- High End Q PLC CPU Model is used

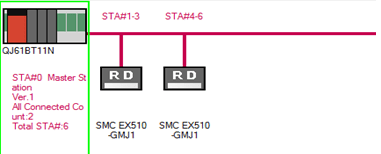

- Field IO & VFD on CC-Link Communication protocol

- No. of PID Loop used for maintain the temperature , flow as per Process

- Melsec Navigator Software is used

- Programming platform is Structure , Function Block and Label Type

- OEM Standard Programing prototype is used

- Two PLC communication with each other on CC-Link IE protocol

Features

- System with 256 DI/DO & 48 AI/AO

- TAD PLC with GOT & Remote IO on field

- Critical part was to Tune all PID

- VFD Communication on CC-Link

- Communication with Alsafe PLC & TAD PLC for Process cycle was crucial

- GOT with Process Monitor & animation

- Temperature of System is ultra High & refer as UHT technology

- GOT with2 Language options English and Japanese

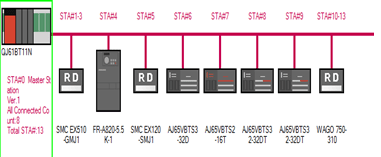

Configuration

- PLC – Q Series with CC-Link.

- GOT- GT27 Series.

- VFD- FR-A Series.

- Remote IO Cards

System Layout and HMI