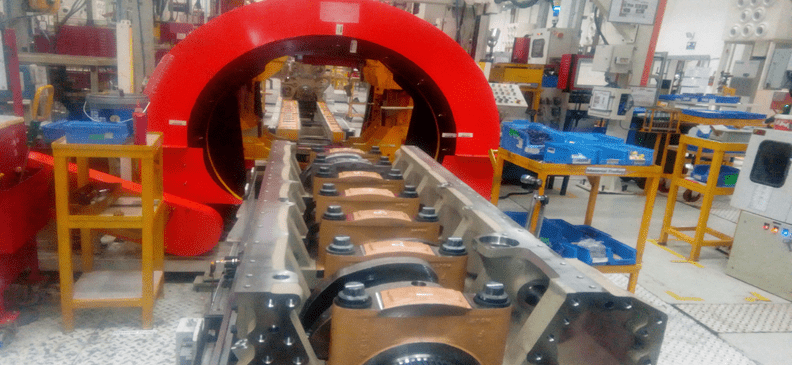

ENGINE ASSEMBLY LINE

- This PLC-Scada based System is developed for a world leader in the design and manufacture of engines and power generation equipment

Operation Philosophy

- The SCADA/PLC System is used for barcode tracking of different assembly parts as the GENSET is being build along the assembly line

- Setability /Scanning and traceability of 241 different components

- Storing RTC based data of every component as the GENSETs are build.

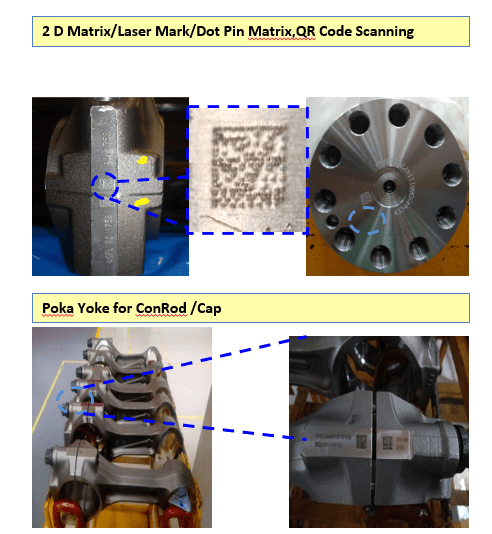

- Scanning of Dot Pin Matrix (DPM Code) , Laser Mark, QR Code on metal/Oily surface

- Poka-Yoke for error free assembly building

- Any Scanner can be used on any Station , providing flexibility of operations

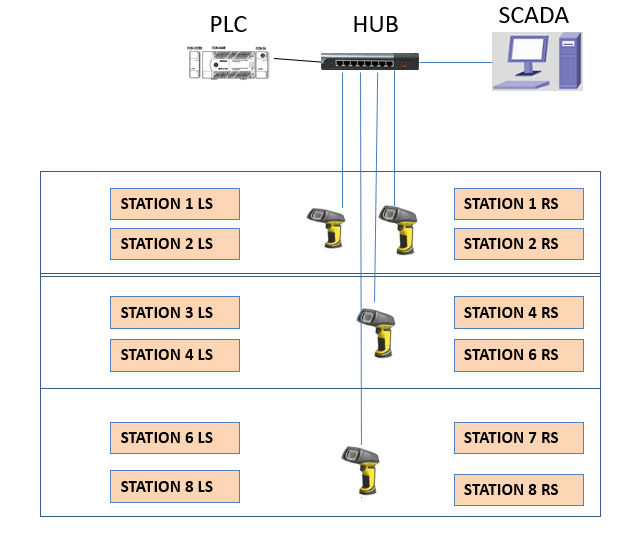

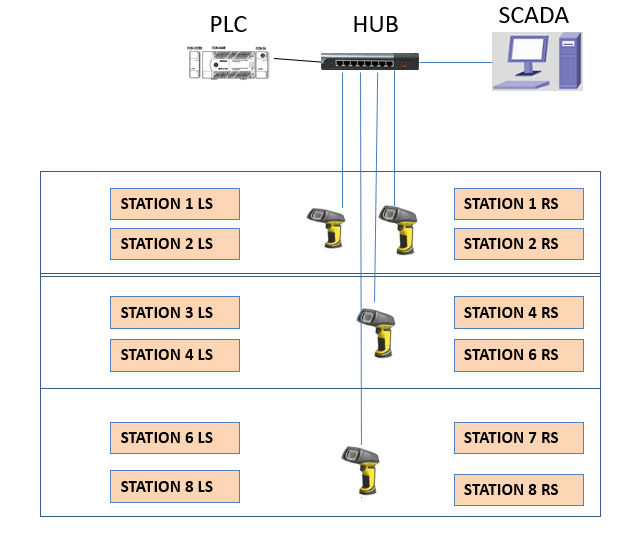

System Layout

There are 8 Different Assembly Stations and 4 wireless Scanners which are used between this Stations

Features

- Image processing based 4 wireless scanners flexibly used on 11 different stations.

- Industrial codes like Dot Pin Matrix (DPM Code) , Laser Mark, QR Code scanning is possible with repeatability.

- Scanning on Oily/Metal surface.

- Poka-Yoke implementation for mistake proof assembly.

- Total Engine Assembly standard report at the End

- Flexibility for component setting

- In case of Customer complaints historical data tracing is possible

- Response time to customer is improved.

- Quality of assembly is improved.

- Production time is reduced.

Configuration

- PLC : FX 5U

- Scanner : wireless 2D DPM Scanners-4Nos.

- SCADA : Elipse 2.29