6 And 9 Speed Assembly System

Operation Philosophy

What the System Does

A System for bar code tracking for transmissions as they are build on the assembly line

TA database to store quality data generated as transmissions are build.he

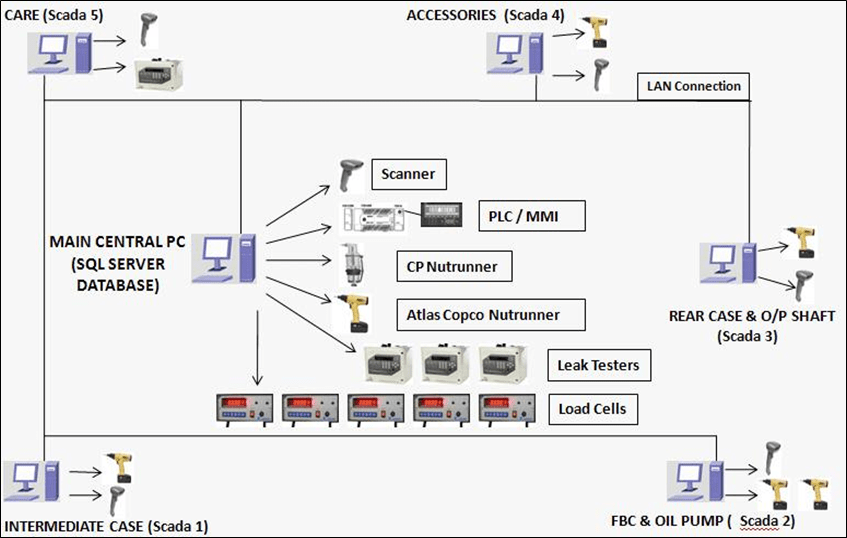

Created links with nut runners, leak testers and load cells for automated transfer and logging of data

Created a user interface application for operators to enter and track quality data.

System Layout

Features

- Poka-yoke system for Error Free high productivity.

- Industrial recommended scanner base system.

- Reduces Transmission rejection due to interlock between software and hardware.

- Maintaining strong database for keeping the track of data and operators according to transmission sub assembly

- Easy for finding the station name and parameter name for Incomplete Transmission.

- Having facility for Reworking Transmission.

- Automatic reports generation.

- Flexible system can easily debug in case of alarms/faults.

- Rejection and rework on the assembly line is minimized.

- Historical data of engine assembly can help to track the engine life.

- Production speed and quality is improved.

Configuration

- FX 3U Series PLC

- Elipse SCADA ver 2.29

- GOT

- Industrial PC for SCADA : 6 Nos

- SQL Server 2012