Cylinder Head Inspection

Operation Philosophy

- Cummins India manufactures variety engines and generators.

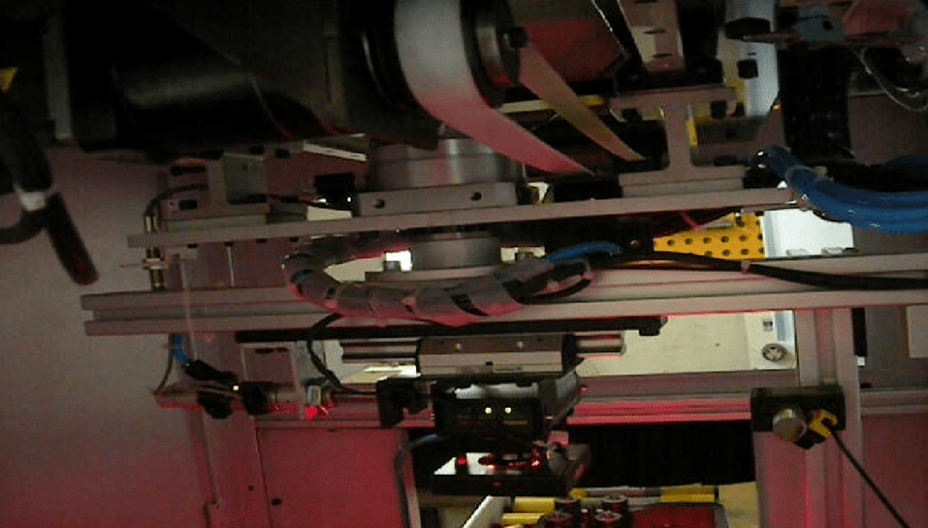

- Vision Inspection system checks the Spring Quality ,Collet size & Injector Bore diameter of Cylinder head.

- Camera Captures the images of Cylinder Head at Specified Locations And Compare these images with Stored Images.

- Mitsubishi Servo achieves the exact position for capturing images in Microns.

- One by one 30 such positions are checked & Good job is declared.

- If Job is defective then GOT will show its Location and defect details for Operator

- Automation helps accuracy while inspection & speed of Inspection Cycle.

System Layout & HMI

Features

- System with 100 I/O with Servo System

- Camera Image Capture Time is in 40 mili-sec

- Servo System Position accuracy is within 30 micron

- Critical point of the system is to Capture good Images within time with precise position

- Light intensity plays a critical part in Inspection

- Three different Modes Manual ,Semi & Auto Mode

- Camera decides the result after image compare

- All Positions data stored in GOT Recipe

Configuration

- PLC – FX-3U Series

- GOT- GT27 Series

- Servo - MRE Series